Conveyor belts are among the most straightforward and flexible types of conveyors. They are used in a wide range of industries and can be expected to serve the purposes required. In the material handling sector, conveyor belts are among the essential tools to invest in. They help in the swift and efficient movement of materials in the assembly line and move products even with complex processes and multiple directional changes involved.

To make them more efficient, different types of conveyor belts are now available to meet specific purposes.

Main Types of Conveyor Belts for Various Industries

Most Widely Used Types of Conveyor Belts

Solid, General-Use Conveyor Belts

This is a common type of conveyor belt for industrial applications and may be made of rubber or fabric.

Solid, rubber conveyor belts are commonly used in mining and milling industries to handle raw materials and aggregates in bulk quantity. PVC conveyor belts are used at grocery stores while conveyor belts made of polyester, neoprene, or rubber are used for baggage handling at airports.

Plastic Interlocking Conveyor Belts

For industries that require regular cleaning and belt change such as food packaging and automotive, plastic interlocking conveyor belts are the preferred choice as it is designed for that type of environment. Fabric and metal belts may also be used to replace plastic belts.

Woven Metal Conveyor Belts

For industries that deal with cooling, drying, and heating processes, this is the type of conveyor belt to use. They are especially suited for the food manufacturing, electronics, and glass manufacturing sectors. Usually, they are made of interlinked chains or wiring which allows airflow while the product is carried.

Hinged Conveyor Belts

Made of metal, hinged conveyor belts are very sturdy and suit rigorous processes. They are used to handle scrap and small products for recycling. They have a flat and solid surface that rotates around the pulley through their interlocking hinges.

Filter Conveyor Belts

This type of conveyor belt is commonly used in water treatment industries to drain out excess fluids or toxins. Filter belts are the preferred type of conveyor belts as they allow particles to pass through a filter instead of being carried by the conveyor system.

Most Common Types of Conveyor Belts for Industrial Applications

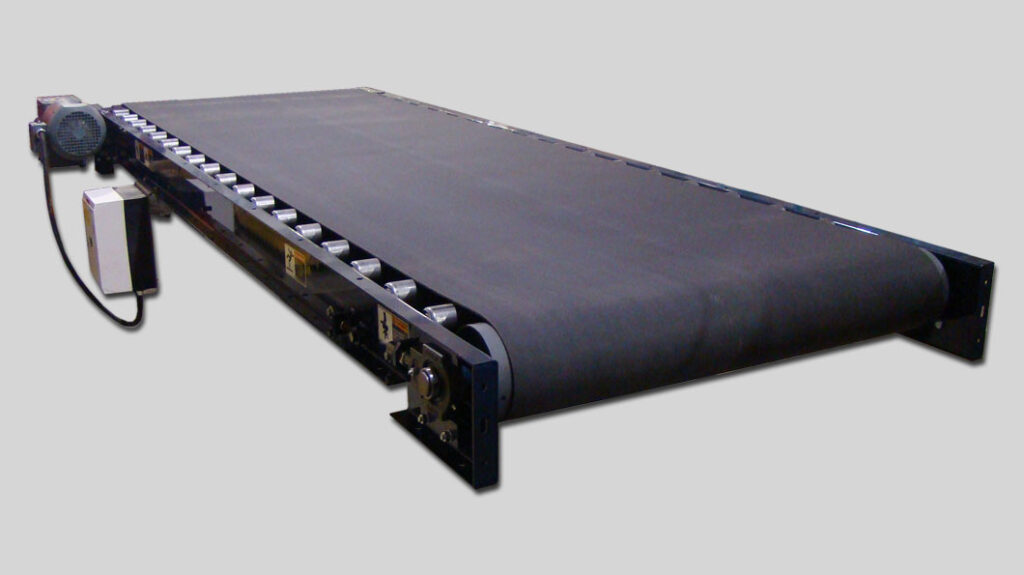

1. Flat-Bed Conveyor Belt

Source: https://omni.com/products/belt-conveyor/

This type of conveyor belt uses a number of powered pulleys. It is commonly used and preferred due to its easy adaptability. It can also convey small and irregularly shaped items without causing damage.

Flat conveyor belts are suited for industrial applications including wash-down areas and assembly lines.

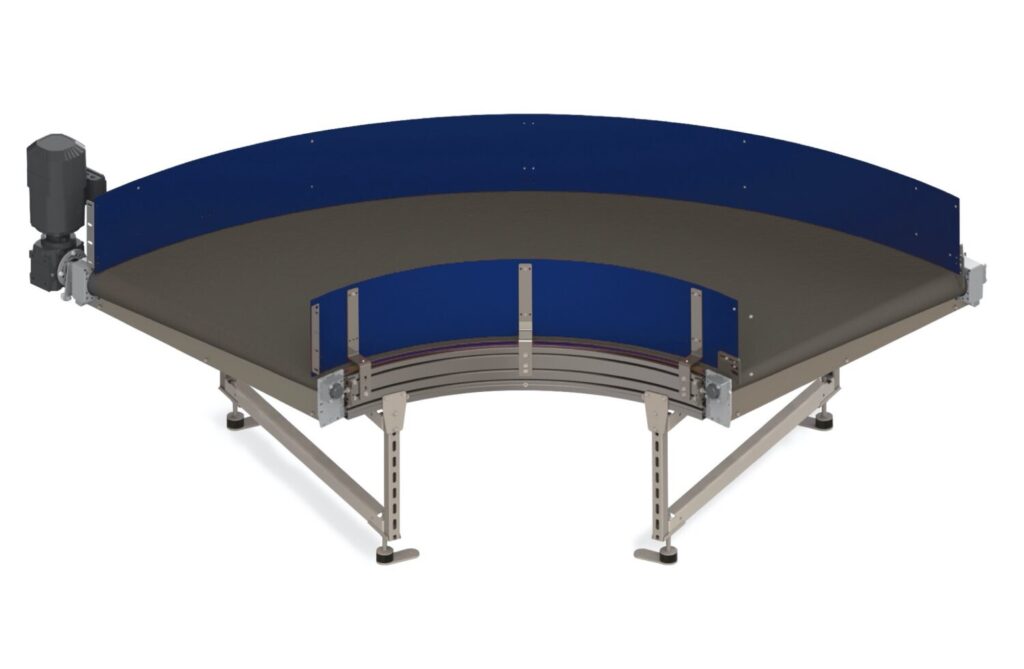

2. Curved Conveyor Belt

Source: https://fmhconveyors.com/products/curved-belt-conveyors/

For carrying materials around the floor corners or making tight transfers, a curved belt conveyor is the best choice. It allows the use of available floor space as its frame features a unique curve that can go up to 180°. This type of conveyor belt is most suited for bag-handling systems.

3. Roller Bed Conveyor Belt

Source: https://www.grainger.com/product/ASHLAND-CONVEYOR-Belt-Conveyor-30-in-Belt-Wd-42X876

This type of conveyor belt has a surface that is composed of rollers that match various production requirements including the weight and speed of products that will move along the belt. The number of rollers for this belt conveyor depends on the distance between the two ends. The greater the distance, the greater the number of rollers needed.

The applications of roller bed conveyor belts include packing, sorting, assembling, inspecting, and transporting such as in sorting facilities and baggage handling systems.

4. Modular Conveyor Belt

Source: https://in-bakery.com/the-advantages-of-plastic-modular-belt/

This is generally made of hard plastic and comes with individual and interlocking belts to form a single loop. It is easy to clean and proves to be a cost-efficient option as its segments may be removed and replaced individually instead of discarding the entire conveyor belt.

Modular conveyor belts are suited for metal detection, carrying food products, and applications where fluid must be drained or retained while on the conveyor.

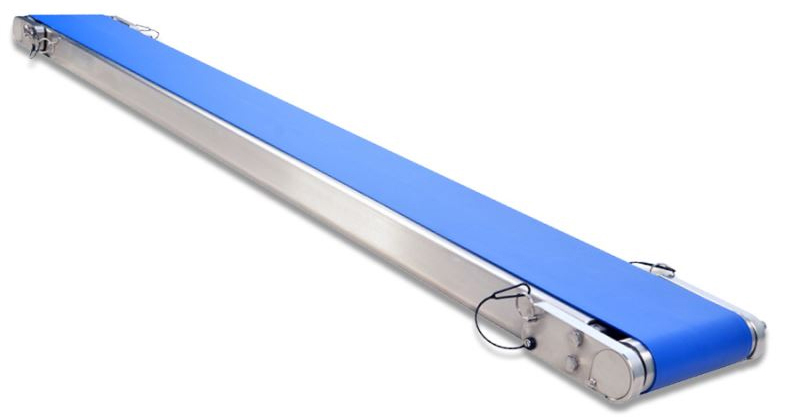

5. Sanitary and Washdown Conveyor Belts

Source: https://www.conovey.com/our-products/hydroclean-series-conveyor/

Manufacturing industries that require intensive washing and sterilization such as food and pharmaceuticals can rely on this type of belt conveyor. Sanitary and washdown conveyor belts can withstand sanitary procedures in compliance with industry standards. They are also resistant to extreme temperatures and can effectively handle wet and greasy items. Commonly, these belt conveyors are paired with flat wire belts to allow easy maintenance.

6. Cleated Conveyor Belt

Source: https://www.dornerconveyors.com/asia/products/3200-series/3200-belted/cleated-belt

Vertical cleats make up the design of this conveyor belt, thus its name. Cleats are essential to prevent loose materials from being lost during inclines and declines. They also allow consistent spacing between items.

Cleated conveyor belts are available in various shapes. Aside from their design differences, each cleated conveyor belt has specific purposes.

● Inverted Capital “T” Cleat – this is a type of conveyor belt with a cleat that stands perpendicular to the belt surface. This intends to provide the support and flexibility required in handling sensitive items. Some of its applications include the transport of small parts, food products, and packaged items.

● Forward-Leaning Capital “L” Cleat – the wide base of this cleat makes it more resistant to leverage forces. It can carry light to medium-weight bulk materials even on steeper inclines. It may also come with curved faces to allow the scooping of granules.

● Inverted “V.” Cleat – especially suited for the transport of abrasive, heavy, and large-piece bulk materials due to its capacity to withstand heavy impact. Its shape is also 2 inches or less in height to enable a troughing effect.

● Lugs and Pegs – these cleats are used for specific applications such as the promotion of run-off of liquids during the transport of washed fruit or vegetables. They are preferred for their cost efficiency for items like cartons and rods that don’t require support throughout the full belt width. Lugs and pegs may be used for the selective movement of products that are more than a given size or to keep individual products in place.

NOTE: The elevator belt is an offshoot of the cleated belt which is designed with regularly spaced partitions or scoops for the movement of loose materials up a steep incline.

7. Incline or Decline Conveyor Belts

Source: https://omni.com/products/belt-conveyor/

These types of conveyor belts use a center drive, gear motor, and take-up with a single or double nose. The belts have a rough surface that allows the carrying of products at an angle of conveyance–whether inclined or declined. Their applications include the transport of products to different elevations without getting them off the line.

8. Specialty Conveyor Belts

Source: https://www.mknorthamerica.com/engineered-solutions/specialty-belting/

As the name suggests, these belt conveyors are suited for specialized applications. They come in various types to perform specific purposes.

● Magnetic Conveyor Belts – designed for the transport of materials that contain iron. They come with electromagnets that are placed within the bed of the conveyor.

● Sandwich Belt Conveyors – this specialized conveyor belt system features two face-to-face belts that help secure carry items at steep inclines or up a vertical run.

● Vacuum Conveyor Belts – especially suited for light products, this type of conveyor belt has a suction feature to keep sheets of paper, leaflets, and other light materials on the line even at high speeds and inclines.

● Fiberglass Conveyor Belts – this type of conveyor belt is made of fiberglass and is most preferred for applications that involve extreme temperatures.

● Metal Nub Conveyor Belts – equipped with metal nubs, this type of conveyor belt is suited for the handling of complex machines including their parts.

● Narrow-Width Conveyor Belts – designed to handle small items.

● Back-lit Conveyor Belts – designed with a light fixture which helps in quality control.

Conveyor belts are useful and aid in cost-efficient operations. Fortunately, there are different types of conveyor belts that meet the particular specifications of every industry, making it easier to find the right machine based on each business’ requirements.

Hayama Industrial Corporation established industry leadership by supporting the manufacturing operations of both local and multi-national companies. Comprised of experts in conceptualization, fabrication and installation services, we can provide the type of conveyor you need to optimize your processes. Send us a message, so we can discuss your requirements.

Recent Comments